Background Reasons

to purchase an M60: Disaster: We put actual M-60 slings on both and mounted the side with an actual

M-60 bandoleer and string of dummy rounds which made both

look considerably better. We did

quite well with the sale of our surplus M-60 and our buyer

is delighted with the gun last we heard.†

We would have loved to have 2 for the team but just

couldnít justify it.† Neither of us looks enough like Sylvester Stalone! About the TOP M60: Firing the M60 is quite fun, it has an impressive rate of fire and reasonable velocity.† While the rate of fire is awesome, the velocity is slightly less than that of your average stock Tokyo Marui AEG (about 260 fps.)† For this weapon to match its intimidating looks and justify its weight my dad and I decided† when it jammed again to dump the dough that we made from selling the one M60 towards upgrading the other. The final decision was made when our M60 stopped firing.† Either way I had to go into it.† I had to unjam it once because my dad (genius that he is) thought, well instead of upgrading it, letís just put .12 gram BBís in it!† That will give it a higher velocity and most likely the range.† Since it was used in suppression role it wouldnít need accuracyÖ WARNING! 12 Gram BBs should never be used in a TOP BB gun.† It jammed BBís from an inch into the barrel all the way to the loading mechanism.† Just to unjam it, I essentially had to strip it half way down. †The TOP barrel takes a ďzĒ shaped turn so itís not just a case of using a rod to unjam it. It was fixed for now and my confidence was boyed by the fact that I could take it apart and put it back together.† The

next time it jammed the problem was more involved.†

The loading mechanism wasnít working.†

I knew Iíd have to open this gun up once again.† At this, dad decided to invest in a full upgrade.†

(Something I wanted to do all along!)†

We purchased the Angs cylinder, Angs spring guide,

Angs 1 joule spring, and an entire gear set replacement for

the main gear system (If you didnít know, there are two different

gear sets, one for controlling the spring and cylinder, the

other for the loading mechanism.)†

The total cost in parts was about $240.00.†

As I said itís a complex design. Upgrading Important Advice:

Taking

it Apart: Ok, now that thatís said and done, letís get started.† Obviously put it on safe, Unload

the gun and disconnect the battery.†

You have to start off with removing the rear sight.†

Do this by tightening the adjustment screw until a

bolt sticks out and it exposes a little hole.†

Use your tiny hex wrench and unscrew that tiny thing.†

Remove the nut and unscrew the adjustment screw using

a flathead screw driver on the opposite side.†

Lift out the top portion of the sight.†

Then remove the gold thing and the spring below it.†

This will expose a screw, unscrew it.†

Slide the rest of the sight out to the side.†

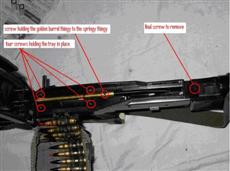

Next comes the tray cover. Take

some tweezers and remove the horseshoe clips located on one

of the sides of the joint.†

NOTE: Careful, these things fly and are nearly impossible

to find!† Slide the

rod out from the joint.† The

tray cover will now be free to remove. Next is the actual tray that holds the bbís.† Unscrew the four screws located on around the

golden barrel thingy.† Also,

unscrew the screw that holds the springy thingy to the golden

barrel thingy (notice how technical my terms are.) Then lift

out the golden barrel thingy.† Remove the last screw in the back of the tray

(located just in front of the hole that locks the tray in

place.† Finally, remove the thing that holds the magazine

bag.† Lift out the tray.

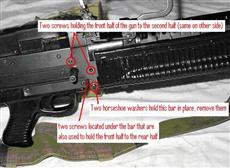

Now you have the bellows and spring exposed. Next you will remove the front half of the gun.† Unscrew the 2 screws located under where the

site was on sides of the gun.†

Then turn the Pig on its back and remove the rod located

on the bottom (made for use on a tripod.) This rod is also

held in place using horse shoe washers.† This time you must remove both of them and once

again, be careful!† Once

the rod is removed, two hex screws are revealed.†

Unscrew them.† Then

take a larger hex wrench and remove the hex screw located

just in front of the trigger.† Now the front half of the gun is free to slide

off.† Proceed to remove

the front half of the gun. The

bellows and spring will now be removed.† Unscrew the bottom two screws located on the

bottom row of screws.† Do

the same thing on the other side.†

Now the bellows system and the spring portion will

lift out.† Unscrew these

two screws on the portion you just lifted out.† Now the two silver bars that stabilize the bellows

system are loose and will slide out.†

The spring will come out with the spring guide as well

(careful, it can launch.)

Once you have this done, attach the piston to the piston head

and use the same bar that held the piston to the bellows system

together to hold the piston head to the piston.†

Put on the rubber ring that came with the cylinder

set on the piston head and two on the cylinder itself. †Add

the grease to the cylinder and itís mechanism to ensure a

smooth action.† Assembling this part is slightly different than disassembling

it.† You wonít use the

silver bars used for the bellows system to hold it in place.

†Instead, you will bolt the cylinder directly

to the frame.† Be sure

to put the piston into the cylinder before you screw it in.†

Also, use the screws that came with the new cylinder

and put them in the front two holes that hold the cylinder

in place.† Next put in the new spring and the new spring

guide. Next you have a crossroads, if you are not planning on replacing the gears; you are done and can now reassemble the gun.† If you plan on continuing and replacing the gears, youíve got more to do! Your final thing to do is the most annoying.† Start off by removing the stock.† Unscrew the four screws located on both sides of the stock. Then remove the large screw in the back.† The stock with slide off and expose the motor and fuse. Unscrew the cover with the loading mechanism and remove this

plastic cover.† This

holds the second gear system that turns the loading mechanism.

Now remove the thin metallic piece that goes around the long

metal rod running from the motor to the gearbox.††

Results: External

Links: Site links: TBA Comment on this review in the forums Last modified: Sunday, May 18, 2003 7:54 PM Copyright 2003 ArniesAirsoft

|